What turns a multi-million dollar warehouse project into a long-term operational advantage instead of a painful, costly detour?

It’s not just the technology. It’s the strategy behind how it’s implemented.

Today, warehouse environments are not only complex. They are unforgiving. On top of that, rapid shifts in consumer demand, tighter labor markets, rising operational costs, and tariffs have made the successful execution of warehouse management projects far more challenging than ever before. Many organizations invest in robust warehouse management systems (WMS), only to realize, often too late, that deployment without strategic consulting leads to misalignment, inefficiency, and delays in realizing ROI.

The stakes are high:

- Are your warehouse workflows truly ready for new technology?

- Are hidden inefficiencies or process gaps going to derail your go-live?

- Is your team prepared to adapt, scale, and manage what comes next, i.e., Change Management?

Seasoned consulting fills the critical gap between technology and operational reality. It’s a support and the foundation of the warehouse project's success. From needs assessment and system design to change management and long-term optimization, consulting ensures every layer of the project, technical and human, works in sync around the globe.

At Smart IS, we’ve seen the full spectrum of warehouse initiatives across industries, scales, and maturity levels. Drawing from over 35 years of experience in Blue Yonder WMS consulting, we know where projects succeed and where they often stall.

This blog explores why expert consulting is essential to the success of modern warehouse projects, highlighting how it bridges the gap between technology and operational performance.

Technology Alone Doesn’t Guarantee Operational Readiness

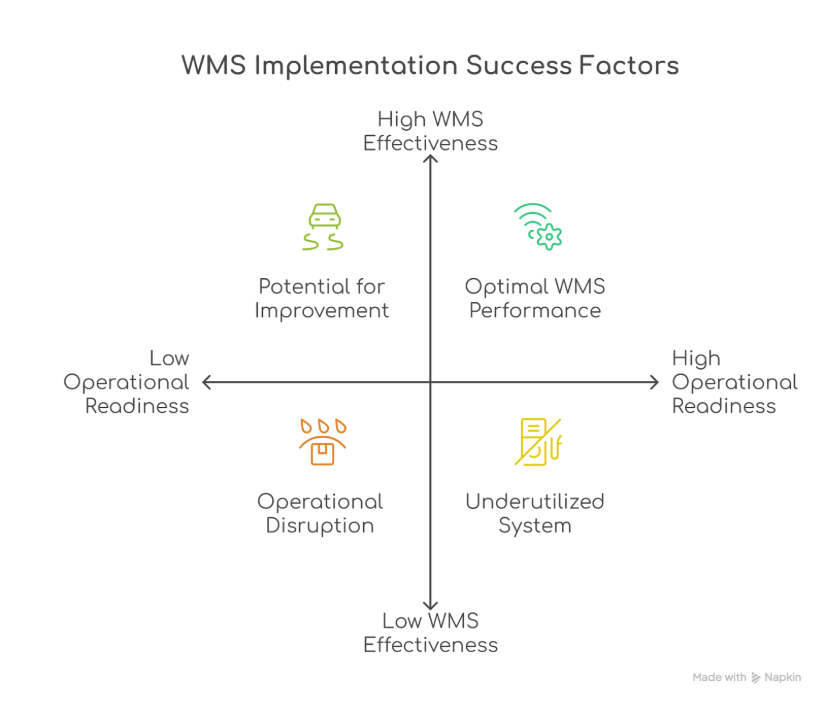

Investing in a top-tier Warehouse Management System like Blue Yonder WMS is no longer a competitive differentiator; it’s a baseline requirement. However, the assumption that a new system will automatically resolve inefficiencies is fundamentally flawed. The reality is that WMS platforms, while robust, are only as effective as the operational environments they are deployed into. Without readiness across infrastructure, processes, and people, even the most sophisticated platforms can underperform.

This is where consulting becomes indispensable. Seasoned WMS consultants begin by conducting a comprehensive assessment of warehouse operations before a single line of code is touched. They examine workflows, process handoffs, inventory control methods, resource allocation, and existing technical architecture to identify alignment gaps.

The outcome is a blueprint that defines how the WMS should be configured, not in isolation, but in response to real-world warehouse behaviors. It also ensures that upstream and downstream systems are accounted for within the design. Without this pre-implementation rigor, organizations risk deploying systems that disrupt operations rather than improve them.

Hidden Process Gaps Can Derail Even the Best WMS

WMS implementations rarely fail due to technical limitations of the software. Most failures stem from poorly understood operational realities that surface mid-project, resulting in delays, scope inflation, or last-minute reconfigurations. These hidden gaps often include inconsistent SOPs, undocumented exceptions, inaccurate location setups, outdated master data, or fragmented stakeholder communication.

Consultants mitigate these risks through structured discovery and gap-fit analysis. By closely engaging with operational stakeholders, they uncover the “tribal knowledge” often missing from system documentation. They map out end-to-end workflows, simulate edge cases, and identify where system logic may conflict with current practices. This process goes beyond technical fit; it evaluates whether the warehouse needs to evolve its own processes to support a more standardized, scalable system model.

In doing so, WMS consultants prevent misalignments that can lead to mispicks, labor inefficiencies, inventory discrepancies, or even full-scale production stoppages post-go-live. Essentially, they de-risk the implementation by pre-solving problems that would otherwise be discovered too late.

Also Read: Agentic AI in Warehouse Operations: From Reactive to Autonomous Systems

Strategic Guidance Accelerates Time-to-Value

Time-to-value has become one of the most critical metrics for warehouse technology initiatives. Organizations can no longer afford 18-month rollouts with delayed ROI. WMS Consulting plays a central role in compressing timelines while preserving the integrity of the solution. Unlike purely technical teams, consultants bring delivery governance and strategic clarity that ensure momentum is maintained across every phase from planning and design to deployment and stabilization.

This acceleration is achieved through a combination of proprietary tools/products and domain knowledge. Experienced consultants establish phased, outcome-driven milestones that keep teams focused on delivering incremental business value, not just technical milestones. They optimize resource planning, prioritize core capabilities, and minimize rework by eliminating ambiguities early in the project lifecycle.

Many, such as we at Smart IS, also offer proprietary accelerators such as automated testing, RF solutions, and data migration tools that reduce development effort and enhance reliability. The result is faster implementation and one that drives earlier adoption, quicker productivity gains, and measurable ROI with precision within months.

Change Management Is as Critical as System Integration

At Smart IS, we have observed that even after the successful implementation of the system, failures can still occur. We have witnessed this firsthand as enterprises that have implemented the system approach us, noting that their teams were not adequately prepared for change management and readiness. According to a report, organizations that implement robust change management strategies, often called “change accelerators", see 264% higher revenue growth compared to those with weaker change effectiveness. This means they achieve 2.6 times more revenue growth.

Even the most technically flawless system can fail if users are not fully bought in or trained to use the system correctly. The human element determines whether technology succeeds or stalls. Resistance to change, lack of training, or unclear communication during transition periods can lead to workarounds that completely negate the value of the new system. Professional WMS Consulting addresses this risk through structured change management. Beyond system configuration, consultants embed change readiness into the project framework.

This includes stakeholder mapping, tailored training programs based on user roles, and simulation-based cutover rehearsals that mimic real operational scenarios. Consultants also help leadership communicate the “why” behind the project, positioning the WMS as an enabler rather than a threat to established routines. During and after go-live, they provide on-site or remote support models that reinforce proper system usage, troubleshoot early issues, and build confidence among end-users.

How Smart IS Delivers End-to-End Value Across Every Phase

Smart IS brings a differentiated consulting model built on three decades of experience within the Blue Yonder ecosystem, with custom toolsets and deep cross-industry insight. What sets Smart IS apart is the ability to connect strategic planning with technical execution. From day one, Smart IS WMS consultants engage in full-spectrum discovery, aligning system design with specific business goals, operational KPIs, and the realities of warehouse floor activity. We work in synergy with client teams to build the right solution for their business needs.

Unlike firms that limit themselves to configuration or go-live support, Smart IS extends its value throughout the entire project lifecycle, including change management, automation readiness, training, and post-deployment hypercare support. Another defining advantage lies in Smart IS’s proprietary tools. Products like SmartVIU for warehouse reporting, SmartRF for RF screen functionalities, and Autest for automated testing were developed internally to solve recurring implementation challenges and are being deployed with clients to streamline delivery, reduce manual errors, and cut deployment time significantly.

These tools are not add-ons; they are built into Smart IS’s consulting DNA, giving clients both velocity and stability. Equally important is Smart IS’s resource quality. With teams of certified solution architects and techno-functional consultants averaging 10 to 15+ years of hands-on WMS experience, clients benefit from consultants who understand business logic, not just system commands. The firm’s global delivery model enables both remote scalability and on-site implementation wherever needed.

Conclusion

Organizations that view consulting as an overhead cost are missing the shift. Today, consulting is the differentiator between functional deployments and transformative outcomes. It's what aligns cross-functional teams, connects disconnected processes, and turns software into a competitive advantage by breaking down the silos within the organization.

If your warehouse initiatives are growing in complexity, now is the time to rethink your approach. Don’t just invest in tools, invest in expertise that understands how to make them work where it counts: on the warehouse floor.

Talk to Smart IS to discover how our Blue Yonder WMS consultants, proprietary accelerators, and cross-industry insight can help you move faster, perform smarter, and scale with confidence.